VIDEO SERIES

Master Your Statistical Process Control Using Live Data

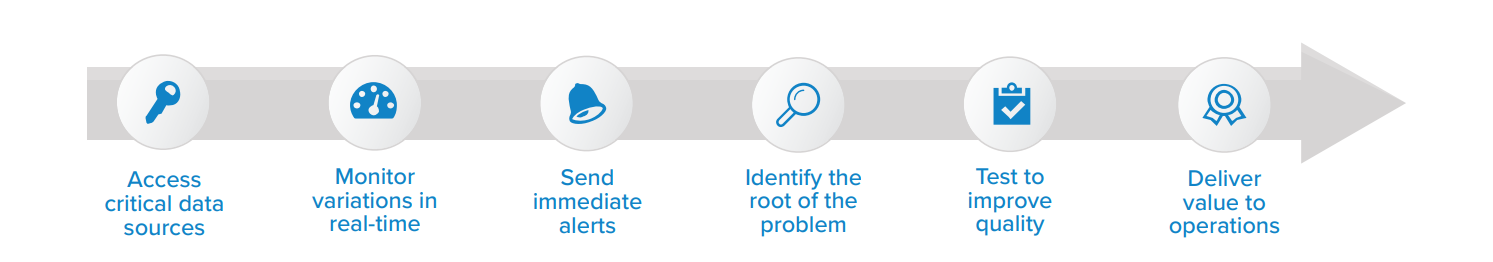

Watch this videos series to discover how Real-Time SPC Powered by Minitab® will help you to:

- Instantly detect out-of-control processes

- Automate your control charts and capability analysis visualizations

- Automatically alert staff to take corrective action

Two Typical Use Cases for Statistical Process Control in Manufacturing

Why You Need Live Statistical Process Control - The Key Benefits

Live Inspection Monitoring & Alerts

Watch how live measurements by operators can be captured to identify reveal out-of-specification measurements in real-time.

Use automatic guidance for the operator and alerts for the engineers to investigate these out-of-control points as they occur.

Automatic Capability Analysis

Watch how to compare capability with specification limits over time, at a glance.

Use capability analysis for different measurements, as well as view the assignable causes and the corrective action taken.

Automatic Out-of-Spec Alerts!

Watch how to use alerts for out-of-control points to notify engineers or stakeholders to respond and investigate.

Use the details of assignable causes, corrective actions and comments to explore and resolve the issue.

Everything You Need for Statistical Process Control

Instantly access, prepare and visualize your process data in one place